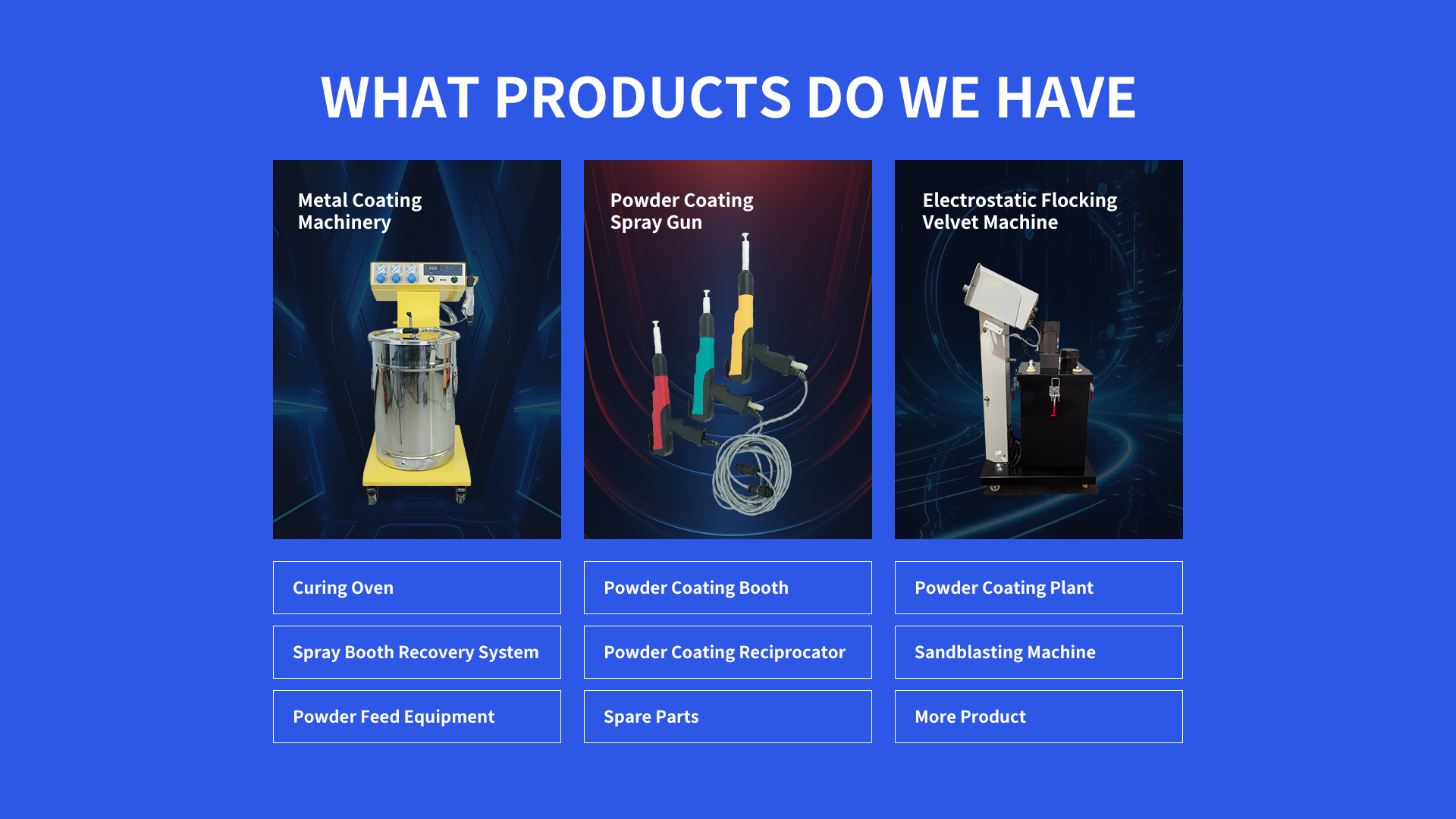

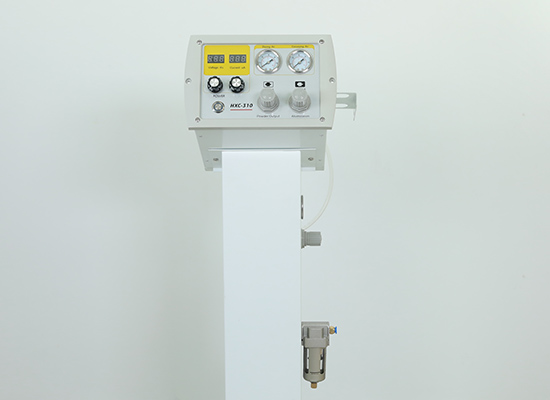

1. Introduction and Structure of Powder Coater MachineA Powder Coater Machine is a vital tool for surface finishing. Its core components include a powder container that holds the coating powder, an electrostatic spray gun which imparts an electric charge to the powder particles for enhanced adhesion, a powder delivery mechanism, and a curing chamber. The spray gun charges the powder, allowing it to stick to the grounded workpiece, and the curing chamber melts and fuses the powder into a solid, protective layer.

2. Application Scenarios of Powder Coater MachinePowder Coater Machines have extensive applications. In the automotive sector, they are used to coat car chassis, exhaust systems, and decorative trims. For the construction industry, they are applied to coat metal building materials like gates, railings, and roofing sheets, providing durability and resistance to the elements. In the electronics industry, they can be used to coat metal casings of devices for protection and aesthetic purposes.

3. Price of Powder Coater MachineThe cost of a

Powder Coater Machine depends on its specifications. Basic models suitable for DIY projects or small workshops can start at around $200. Mid-range machines with improved features such as better powder control and higher efficiency may cost between $500 and $1500. High-end industrial powder coater machines, capable of large-scale production and complex operations, can range from $2000 upwards.

4. Correct Usage Method of Powder Coater MachineTo use a

Powder Coater Machine effectively, start by thoroughly preparing the surface. Clean it to remove dirt, grease, and rust. Then, adjust the powder flow rate and the voltage settings of the spray gun according to the powder type and the size of the workpiece. Maintain a consistent distance of about 6-8 inches from the surface while spraying in a smooth, even motion. After spraying, place the coated item in the curing chamber at the recommended temperature and time for proper curing.

5. How to Select a Powder Coater MachineWhen choosing a

Powder Coater Machine, consider your production scale. For small-scale operations, a portable and cost-effective model is a good choice. For larger production runs, opt for machines with higher powder output, faster curing capabilities, and efficient powder recovery systems. Also, check the reputation of the manufacturer and the availability of after-sales support.

6. Safety Precautions of Powder Coater MachineWhen operating a

Powder Coater Machine, safety should be a top priority. Wear protective equipment such as a dust mask, gloves, and safety goggles to protect against powder inhalation and potential skin and eye contact. Ensure proper ventilation in the work area to prevent the accumulation of powder dust. Keep the machine away from sources of ignition and regularly inspect electrical components for any signs of damage.

7. Rationality Analysis of Powder Coater MachineInvesting in a

Powder Coater Machine is a rational choice. It offers an environmentally friendly coating solution as powder coating generates less waste compared to liquid coatings. It also provides a more uniform and durable finish, which can enhance the product's value and lifespan.

8. Q&A about Powder Coater MachineQ1: Can a powder coater machine coat irregularly shaped objects?A: Yes,

Powder Coater Machines can coat irregularly shaped objects. However, you may need to adjust the spray gun angle and movement to ensure even coating.

Q2: What is the most common problem with a powder coater machine?

A: One common issue is uneven powder coating, which can be caused by improper spray gun settings, inconsistent powder flow, or insufficient surface preparation.

Q3: How long does it take to set up a powder coater machine?

A: For a basic setup, it may take around 15-30 minutes. However, for more complex industrial machines, it could take longer, especially if calibration is required.

Q4: Are there any specific powders for food-grade applications in a powder coater machine?

A: Yes, there are special food-grade powders available that can be used in powder coater machines for applications such as coating food processing equipment.

Q5: Can I upgrade the features of my powder coater machine?

A: In some cases, you can upgrade certain features of your powder coater machine, such as the powder recovery system or the spray gun, depending on the machine's design and compatibility.

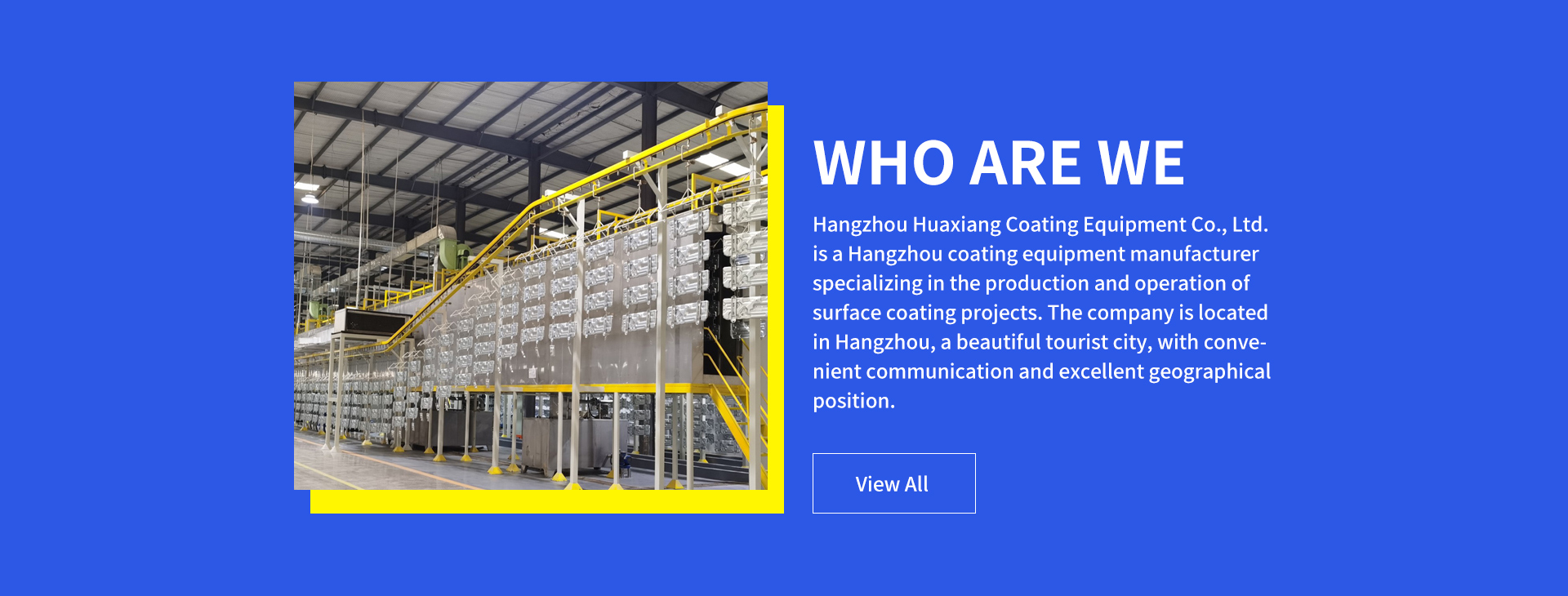

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com